2D X-ray Inspection

2D X-ray Inspection

Overview

2D X-ray inspection is a cutting-edge technology that allows us to see beyond the surface, providing invaluable insights into the integrity, quality, and functionality of a wide range of materials and products.

At its heart, 2D X-ray inspection is an advanced imaging technique that harnesses the penetrating capability of X-rays to generate high-resolution radiographic images. Distinguished by its digital nature, 2D X-ray inspection transcends the limitations of traditional radiography by delivering unparalleled clarity and precision. The process involves directing X-rays through an object or material, with varying levels of attenuation by different substances within it. These attenuated X-rays are then captured by a detector, forming detailed 2D images that allow for the examination of internal structures, hidden features, and potential defects.

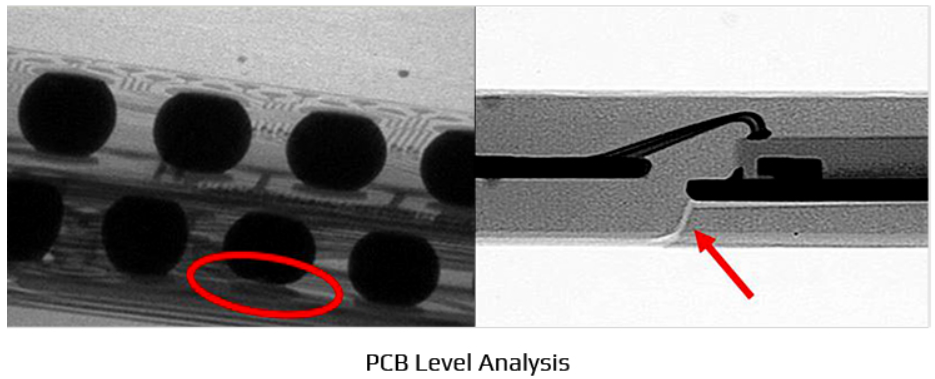

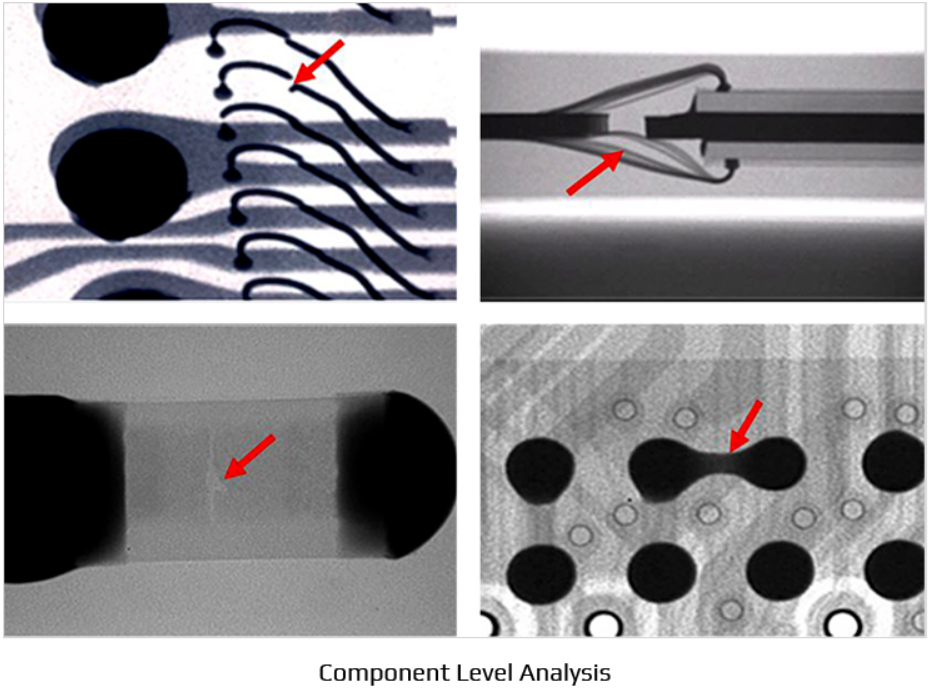

The applications of 2D X-ray inspection span an impressive array of industries and scientific fields, driving innovation and enhancing quality control. In manufacturing, it takes center stage in quality assurance by identifying anomalies such as voids, cracks, misalignments, and soldering irregularities in electronic components and assemblies. The aerospace and automotive sectors rely on 2D X-ray inspection to validate the structural integrity of critical components, ensuring safety and reliability. In materials science, researchers utilize it for materials characterization, facilitating the development of advanced materials tailored to specific properties and applications.

Our 2D X-ray inspection service empowers you to harness the full potential of this transformative technology. Whether you’re conducting rigorous quality control assessments, intricate failure analyses, or pioneering research, our cutting-edge equipment and seasoned technicians guarantee precise and insightful results. We prioritize collaboration, offering tailored 2D X-ray inspection solutions that align with your unique challenges and objectives.

Services

- Inspection of the internal structure – non-destructive

- Failure location identification – non-destructive

Pricing

- Regular service: Starts from $300/hour with 4 – 6 days turnaround. Expedited service available.

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Equipment

AMFIS / AXIS2090

- Tube voltage range: 20 – 90 kV

- Tube current range: 0.19 mA

- Spatial resolution: 0.2 µm

- Sample size: 500 x 600 mm

- Real time x-ray imaging

FAQ

A: 2D X-ray inspection is an imaging technique that uses X-rays to create high-resolution radiographic images of objects, revealing their internal structures and defects. It works by directing X-rays through the object, with varying levels of X-ray attenuation resulting in detailed 2D images.

A: 2D X-ray inspection is used for quality control, failure analysis, and research across industries, including electronics, manufacturing, aerospace, automotive, and materials science.

A: Yes, 2D X-ray inspection is non-destructive, allowing for in-depth examination without damaging the object or material being inspected.

A: 2D X-ray inspection can identify defects such as voids, cracks, misalignments, soldering issues, and internal structural anomalies in components, materials, and assemblies.

A: 2D X-ray inspection can be applied to objects and materials of various sizes, from small electronic components to large assemblies, depending on the capabilities of the X-ray equipment.

A: The duration of 2D X-ray inspection varies based on the complexity and size of the object. It can range from minutes to hours.

A: Yes, 2D X-ray inspection can provide quantitative data on dimensions, defect sizes, and material density, aiding in detailed analysis and characterization.

A: Yes, 2D X-ray inspection is widely used in the electronics industry to inspect components, circuit boards, solder joints, and detect defects or failures.

A: You can request 2D X-ray inspection services from specialized laboratories or analytical service providers. Contact them to discuss your specific inspection needs and arrange for testing.

A: Yes, 2D X-ray inspection can be customized to address specific inspection challenges and requirements, ensuring that the analysis meets your unique objectives.