Nano-Indentation

Nano-Indentation

Overview

Nano-indentation Analysis, often referred to as nanoindentation or simply indentation testing, is a fundamental method in materials science and engineering. It plays a pivotal role in understanding the mechanical behavior of materials, including hardness, elastic modulus, and indentation resistance.

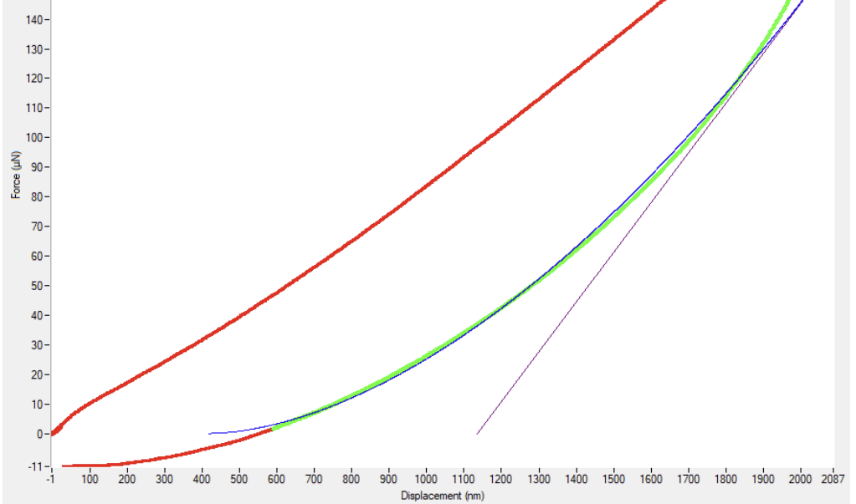

Nano-indentation Analysis operates on the principle of applying a controlled load to a sharp indenter tip (often a diamond) and measuring the resulting indentation depth into the sample. The indenter is typically smaller than a micrometer, allowing for precise measurements at the nanoscale.

As the indenter penetrates the material, force and displacement data are continuously recorded. This data is used to calculate various mechanical properties, including hardness, elastic modulus, and more. Nano-indentation can be performed on a wide range of materials, including metals, ceramics, polymers, composites, and biomaterials.

This technique is particularly valuable for characterizing coatings, thin films, and small-scale structures, as it provides insights into the local mechanical response of materials, even at the submicron level.

Outermost Technology’s Nano-indentation Analysis services offer precise measurements of mechanical properties, enabling you to gain a deeper understanding of material behavior and performance at the nanoscale. Whether you are researching new materials, optimizing product designs, or studying microstructures, our state-of-the-art equipment and experienced analysts are here to support your material characterization needs.

Services

- Hardness

- Plasticity

- Elasticity index

Pricing

- Regular service: Starts from $500 per sample with 5 – 6 days turnaround.

- Relaxed service: Starts from $300 with 7 – 10 days turnaround.

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Equipment

- Features

- Hysitron’s patented capacitive transducer provides industry leading sensitivity and stability.

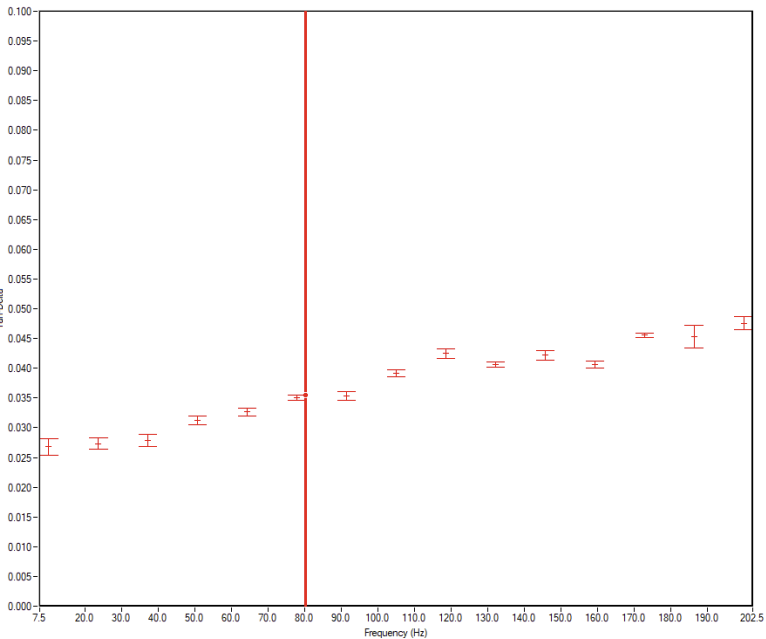

- Hysitron’s performech™ advanced control module with performance leading force and displacement feedback control algorithms with a 78 kHz feedback loop rate and user definable data acquisition rates up to 30 kHz for superior control over all nanomechanical testing techniques.

- Dual head testing capability providing an available force range from ≤30 nN to 10 N for true nano–micro scale connectivity.

- Conforms to ISO 14577 with temperature and humidity measurement.

- Automated testing for high throughput and statistical sampling of materials

- In-situ imaging provides nanometer precision test positioning and the convenience of SPM topography

- Engineered acoustic and thermal enclosure, along with a stable transducer design and active vibration dampening, minimizes test set-up and stabilization time.

- Top-down, high resolution color optics for viewing and selection of testing sites.

- 500 nm resolution staging for precise sample positioning

- Numerous add-ons that provide the widest array of testing capabilities on the market

- Technical specifications

- Load: Resolution: <1 nN, Noise floor: <30 nN, Imaging contact force: <70 nN

- Displacement: Resolution: < 0.02 nm, Noise floor: < 0.2 nm, Drift: <0.05 nm/sec

FAQ

A: Nano-indentation Analysis, often referred to as nanoindentation, is an analytical technique used to probe the mechanical properties of materials at the nanoscale. It measures properties such as hardness, elastic modulus, and indentation resistance.

A: Nano-indentation Analysis involves applying a controlled load to a sharp indenter tip, often made of diamond, and measuring the resulting indentation depth into the sample. Force and displacement data are recorded during the test, which is used to calculate mechanical properties.

A: Nano-indentation can be performed on a wide range of materials, including metals, ceramics, polymers, composites, biomaterials, and thin films. It is suitable for characterizing materials at the nanoscale.

A: Nano-indentation is crucial for characterizing the mechanical properties of coatings and thin films, helping researchers optimize their performance for applications such as wear resistance, corrosion protection, and electronic devices.

A: Nano-indentation Analysis can determine mechanical properties such as hardness, elastic modulus, indentation resistance, and creep behavior. It provides insights into how materials respond to mechanical forces at the nanoscale.

A: Nano-indentation is essential for understanding the mechanical behavior of materials at small scales. It helps researchers and engineers optimize material properties, study microstructures, and assess the performance of coatings and thin films.

A: Yes, nano-indentation is used in quality control to assess the mechanical properties of materials, ensuring they meet specified standards and performance requirements.

A: Nano-indentation finds applications in various industries, including materials science, aerospace, automotive, electronics, biomedical engineering, and coatings technology. It is used wherever precise knowledge of mechanical properties is crucial.

A: Outermost Technology’s Nano-indentation Analysis services offer precise measurements of mechanical properties at the nanoscale. Whether you are developing new materials, optimizing product designs, or conducting research on microstructures, our advanced equipment and experienced analysts provide valuable insights.

A: In biomaterials research, nano-indentation helps assess the mechanical properties of tissues, medical devices, and implants at small scales. It aids in understanding how biomaterials interact with biological systems.