X-ray Reflectometry (XRR)

X-ray Reflectometry (XRR)

Overview

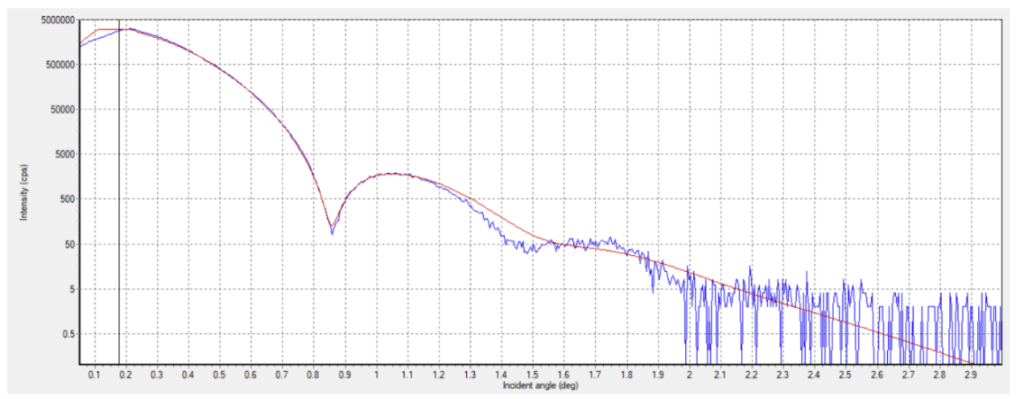

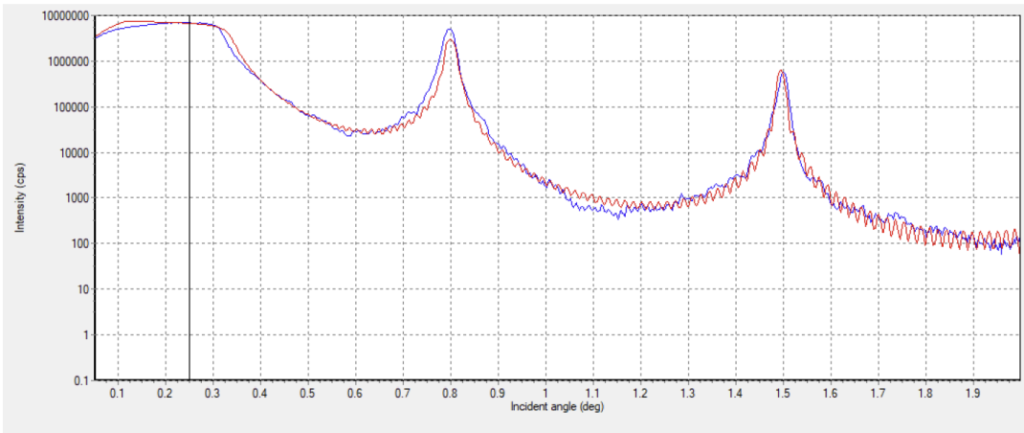

X-ray Reflectometry Analysis, often referred to as X-ray reflectometry or XRR, is a fundamental method in surface science and materials research. It plays a pivotal role in unraveling the intricate details of layered materials, offering insights into layer thickness, density, and roughness at the nanoscale.

X-ray Reflectometry Analysis operates on the principle of X-ray interference. It involves directing a focused beam of X-rays at a specific angle onto the sample’s surface or interface. The X-rays penetrate the sample and interact with the various layers and interfaces within it.

The reflected X-rays are detected and analyzed to determine their intensity as a function of the incident angle. By scrutinizing the interference patterns in the reflected X-rays, X-ray Reflectometry Analysis provides detailed information about the structural characteristics of the sample, including layer thickness, electron density, and surface roughness.

This technique is particularly valuable for characterizing thin films and multilayer coatings in materials ranging from semiconductors to polymers, biomaterials, and more.

Outermost Technology’s X-ray Reflectometry Analysis services offer precise measurements of thin film properties, enabling you to gain a profound understanding of material structures and surface interactions. Whether you are engaged in materials development, optimizing device performance, or conducting surface chemistry studies, our state-of-the-art X-ray equipment and experienced analysts are here to support your material characterization needs.

Services

- XRR analysis for thin film thickness, density, and roughness

Pricing

- Regular service: Starts from $250 per sample with 4 – 5 days turnaround.

- Relaxed service: Starts from $175 with 7 – 10 days turnaround.

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Equipment

- Benefit: Powder diffraction, thin film, SAXS, in-plane scattering, operando measurements

- Technology: Automated high-resolution θ-θ multipurpose X-ray diffractometer (XRD) with expert system Guidance software

- Core attributes: 3 kW sealed X-ray tube, CBO optics, D/teX Ultra 250 silicon strip detector

- Core options: PhotonMax high-flux 9 kW rotating anode X-ray source, in-plane arm (5-axis goniometer), HyPix-3000 high energy resolution 2D HPAD detector, Johansson Kα₁optics

- Computer: External PC, MS Windows® OS, SmartLab Studio II software

- Core dimensions: 1300 (W) x 1880 (H) x 1300 (D) mm

- Mass (core unit): Approx. 750 kg (sealed tube), 850 kg (rotating anode)

- Power requirements: 3Ø, 200 V 50/60 Hz, 30 A (sealed tube) or 60 A (rotating anode)

FAQ

A: X-ray Reflectometry Analysis, or XRR, is an analytical technique used to investigate the surface and interface structures of thin films, multilayer coatings, and nanostructures. It provides information about layer thickness, electron density, and surface roughness at the nanoscale.

A: XRR works by directing a focused beam of X-rays at a specific angle onto a sample’s surface or interface. The X-rays penetrate the sample and interact with the layers and interfaces within it. The reflected X-rays are detected and analyzed to determine their intensity as a function of the incident angle, revealing structural characteristics.

A: Yes, XRR is a non-destructive technique, which means it does not damage the sample during analysis. This makes it suitable for studying delicate or valuable materials.

A: The advantages of XRR analysis include its ability to provide high-resolution structural information at the nanoscale, non-destructiveness, and versatility in analyzing a wide range of materials and surface structures.

A: XRR can be applied to a wide range of materials, including semiconductors, polymers, metals, ceramics, biomaterials, and more. It is particularly valuable for characterizing thin films, coatings, and layered structures.

A: XRR provides information about the layer thickness, electron density, and surface roughness of a sample’s surface and interfaces. It offers insights into the structural properties of thin films and multilayer coatings.

A: XRR analysis is used in various industries, including materials science, electronics, semiconductor manufacturing, thin-film technology, and surface chemistry. It is essential for optimizing material properties and quality control.

A: In materials research and development, XRR analysis aids in characterizing the structural properties of thin films and coatings. It helps researchers optimize material properties and understand the impact of surface structures on performance.

A: Outermost Technology’s XRR Analysis services offer precise measurements of thin film properties and surface structures. Whether you are involved in materials development, device optimization, or surface chemistry studies, our advanced equipment and experienced analysts provide valuable insights.

A: In semiconductor manufacturing, XRR analysis can help assess the thickness and quality of thin films used in device fabrication. It ensures that semiconductor materials meet the required specifications for performance and reliability.