X-ray Photoelectron Spectroscopy (XPS)

X-ray Photoelectron Spectroscopy (XPS)

Overview

X-ray Photoelectron Spectroscopy (XPS) is a non-destructive technique used to identify surface atoms and their chemical bonding states.

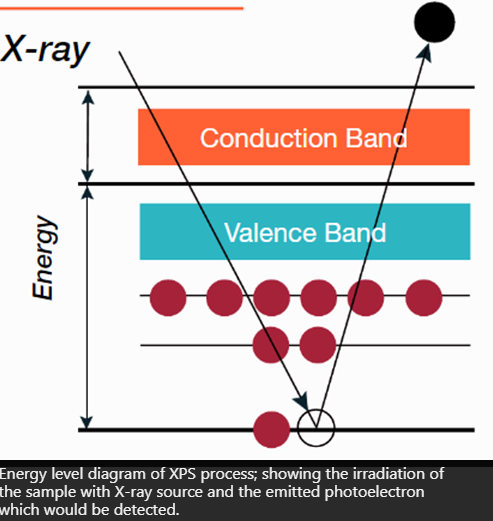

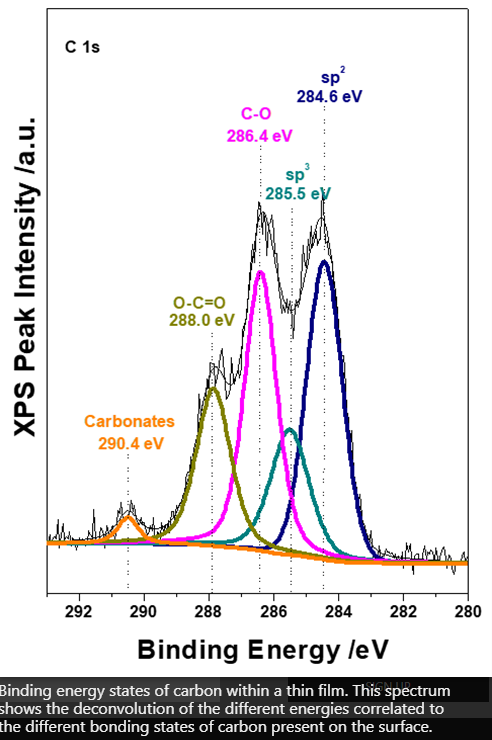

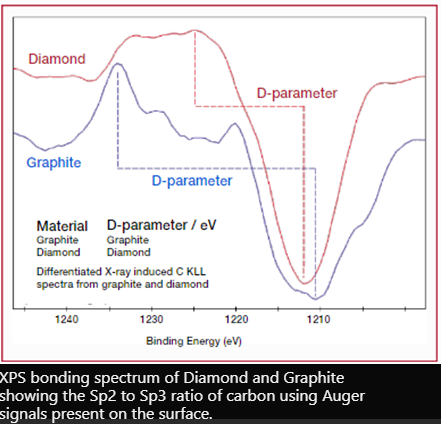

A standard XPS setup directs an X-ray onto the sample surface which causes photoelectrons to be emitted. These photoelectrons are then captured, and their energies are analyzed to determine the type of elements that are present on the surface. As the energy levels of electrons vary slightly depending on bonding states, XPS can provide quantitative bonding state information through the peak deconvolution. Most XPS systems are equipped with a sputtering beam to clean the surface and to understand the material composition bonding states as a function of depth. Although X-rays penetrate deep into materials, only electrons from the top 10 nm surface make it to the detector, which makes the technology very surface sensitive.

To read more on XPS, you can read our Key Tech brochure.

Services

- Outermost Technology provides state-of-the-art XPS with an integrated report included with the resulting data for the following analyses:

- Surface Scan: Non-Destructive Quantitative analysis up to 10 nm in depth

- Depth Profile: Destructive Quantitative analysis up to 10 µm in depth

- Angle Resolved: Non-Destructive Depth Profile up to 10 nm in depth

- Powder: Compositional Analysis of Powder Material

Pricing

- Surface analysis: Starts from $300/sample with 4 – 5 days of turnaround.

- Depth-profiling: Starts from $600/sample with 4 – 5 days of turnaround.

- Powder analysis: Starts from $500/sample with 4 – 5 days of turnaround.

Equipment

- Analyzer — 180° double focusing hemispherical analyzer with 128-channel detector

- X-ray source — Al Ka micro-focused monochromator with variable spot size

- Ion Gun — Energy range 100-4000 eV

- Charge Compensation — Dual beam source

- Sample Size — 4-axis sample stage, 60 x 60 mm sample area, 20 mm maximum sample thickness

- Options — Vacuum transfer module, tilt module for ARXPS, sample bias module

FAQ

A: XPS is a surface-sensitive analytical technique that measures the elemental composition, empirical formula, chemical state, and electronic state of the elements within a material.

A: XPS works by irradiating a material with X-rays and measuring the kinetic energy and number of electrons that escape from the top 1-10 nm of the material’s surface.

A: XPS can provide detailed information about the surface composition, chemical states of elements, and the thickness and uniformity of thin films on a surface.

A: XPS can analyze a wide range of samples, including metals, semiconductors, polymers, glasses, ceramics, and biological materials.

A: XPS is considered non-destructive as it typically does not alter the bulk properties of a sample. However, it can cause minor surface damage under certain conditions.

A: XPS is highly sensitive for surface analysis and can detect elements at the parts-per-million (ppm) level on the sample surface.

A: Yes, XPS can distinguish between different oxidation states of elements based on the chemical shift in the binding energy of electrons.

A: XPS analysis is limited to the very surface of materials and requires a vacuum environment. It also cannot detect light elements like hydrogen and helium.

A: XPS provides detailed chemical state information and is less destructive than SIMS. Compared to AES, XPS generally has better detection limits and provides more straightforward quantification.

A: Samples must be vacuum-compatible and typically need to be dry and free of contaminants. Sample size and shape can vary, but they must fit within the analysis chamber.