Tensile and Bending Tests

Tensile and Bending Tests

Overview

The tensile test and bending test are fundamental methods used to evaluate the mechanical properties of materials, particularly their strength, stiffness, and deformation characteristics. In the tensile test, a standardized test specimen is subjected to a gradually increasing tensile load until failure occurs, while in the bending test, a test specimen is subjected to a bending moment until failure occurs. These tests provide valuable insights into the behavior of materials under tension and bending stress, aiding engineers and scientists in material selection, design optimization, and quality assurance across various industries.

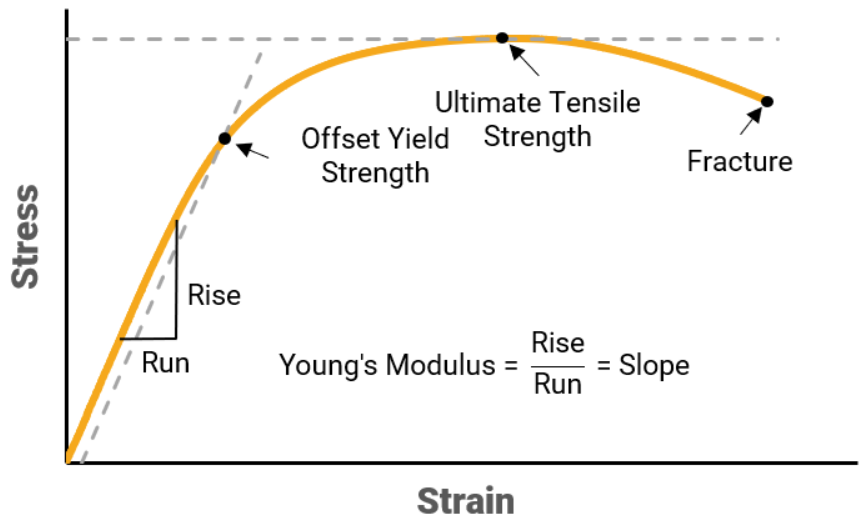

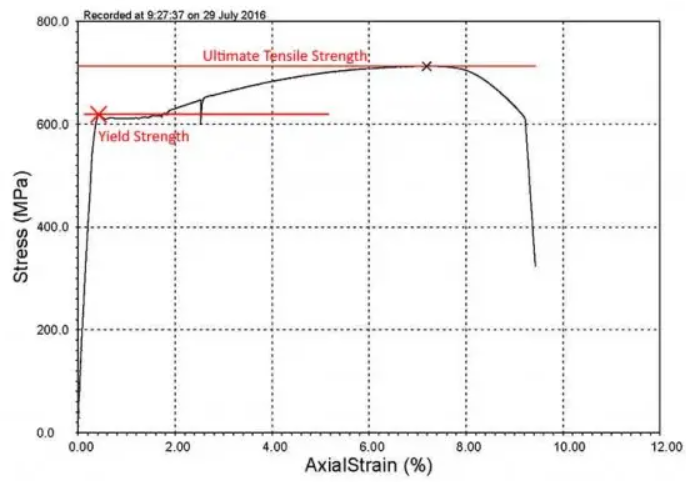

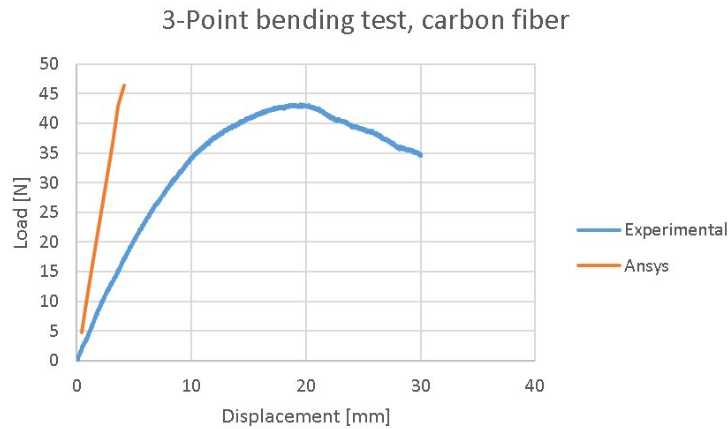

During the tensile test, a test specimen is clamped at both ends and subjected to an axial pulling force, leading to deformation along its axis. The relationship between applied load and resulting deformation is recorded on a stress-strain curve, providing data on ultimate tensile strength, yield strength, and elongation. In the bending test, a test specimen is supported at two points or along its length and subjected to a transverse load, causing it to bend. The relationship between applied load and resulting deformation is recorded, offering insights into flexural strength, modulus of elasticity, and deformation behavior.

Tensile testing and bending testing find widespread applications across industries such as aerospace, automotive, construction, manufacturing, and materials science. Tensile testing helps assess the suitability of materials for structural components, fasteners, and load-bearing elements, enabling engineers to design products with optimal strength and durability. Bending testing is essential for evaluating the structural performance of beams, panels, and other components subjected to bending loads, facilitating structural design, analysis, and optimization.

Both tensile testing and bending testing provide quantitative data on material properties, allowing engineers to make informed decisions in material selection, product design, and process optimization. Tensile testing helps identify material defects, assess material behavior under tension, and verify compliance with industry standards and specifications. Bending testing evaluates the load-bearing capacity, stiffness, and deformation characteristics of materials, supporting structural design, performance evaluation, and quality assurance efforts.

Services

- Tensile: Ultimate Tensile Strength (UTS), Yield Strength, Elongation, Young’s Modulus, and Reduction in Area

- Bending: Flexural Strength (or Modulus of Rupture), Modulus of Elasticity (Flexural Modulus), Bending Moment, Deflection, and Curvature

Pricing

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Equipment

55 ton Guided Bend and Tensile Tester

- Performs guided bend and tensile strength pull tests

- Accurately perform tests up to 100,500 pounds of pressure

- Optional choice of die and plunger sets to meet ASME or API code

- Comes standard with .375 ASME die and plunger set and 1/4-1/2″ pulling jaws

- 3 pulling jaw size options

- Includes a liquid-filled, certified gauge with high level indicator, 2-speed manual pump, (1) Set of pulling jaws, (1) Die and plunger set, (1) carrying case

- Quality constructed for rugged strength

- Transportable – heavy but can be moved

- Manufactured in the USA

Sample Data

- Strain and Stress (Reference from https://standardmechanics.com/tensile-testing/)

- UTS and Yield Strength (Reference from https://www.admet.com/testing-applications/test-types/tension-testing/)

- Three point test bending of carbon fiber (Reference from https://forum.ansys.com/forums/topic/3-point-bending-test-of-carbon-fiber/)

FAQ

A: The tensile test evaluates a material’s response to pulling forces, measuring parameters such as ultimate tensile strength and yield strength. In contrast, the bending test assesses a material’s behavior under bending loads, measuring flexural strength and stiffness.

A: In a tensile test, a specimen is clamped at both ends and subjected to an axial pulling force until failure. In a bending test, a specimen is supported at two points or along its length and subjected to a transverse load until failure occurs.

A: Tensile and bending tests are conducted on a wide range of materials, including metals, alloys, plastics, ceramics, and composites, to assess their mechanical properties and structural performance.

A: Tensile tests measure parameters such as ultimate tensile strength, yield strength, elongation, modulus of elasticity (Young’s Modulus), and reduction in area.

A: Bending tests measure parameters such as flexural strength (or modulus of rupture), modulus of elasticity (flexural modulus), bending moment, deflection, and curvature.

A: Tensile and bending tests are used for material characterization, quality control, material selection, structural design, and performance evaluation in industries such as aerospace, automotive, construction, and manufacturing.

A: Engineers analyze the stress-strain curves generated during tensile tests to determine material properties such as strength, ductility, and stiffness. In bending tests, they assess parameters such as flexural strength, modulus of elasticity, and deformation behavior.

A: Factors such as specimen preparation, testing conditions (e.g., temperature, humidity), loading rate, and specimen geometry can influence the outcomes of tensile and bending tests.

A: Yes, various organizations such as ASTM International, ISO, and EN provide standardized procedures and guidelines for conducting tensile and bending tests, ensuring consistency and accuracy in testing protocols.

A: The data obtained from tensile and bending tests help engineers optimize material selection, design structural components, assess manufacturing processes, and ensure product performance and reliability in real-world applications.