Process and Functional Block Analysis

Process and Functional Block Analysis

Overview

Our Process Analysis for IC Devices service offers specialized expertise in evaluating and optimizing semiconductor manufacturing processes, including functional block analysis, to cater to Research and Development (R&D) initiatives and IT litigation support. Focusing on precision, reliability, and legal compliance, we deliver comprehensive analytical solutions to aid clients in understanding, refining, and safeguarding their semiconductor fabrication processes.

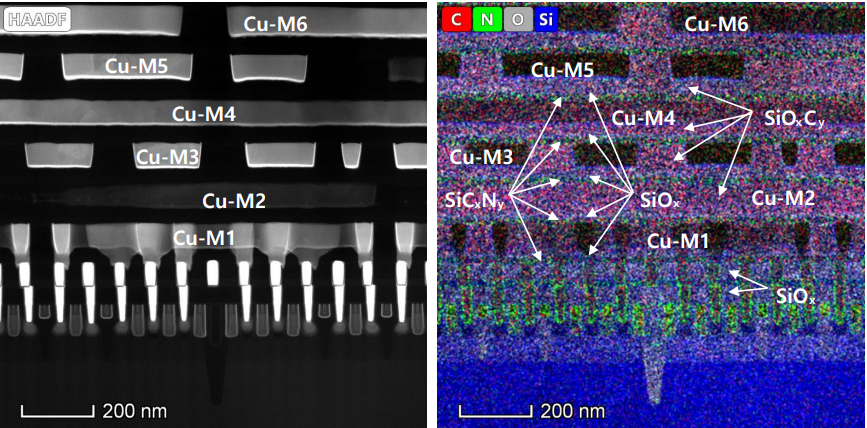

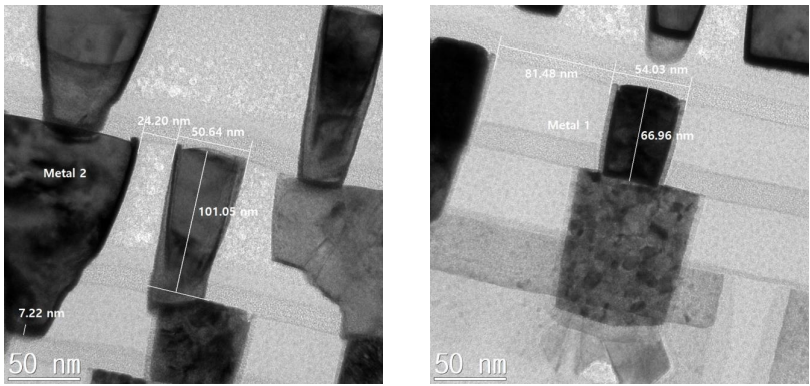

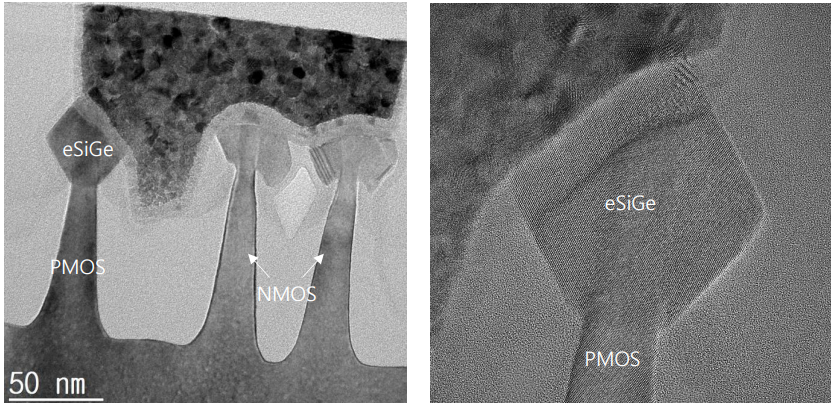

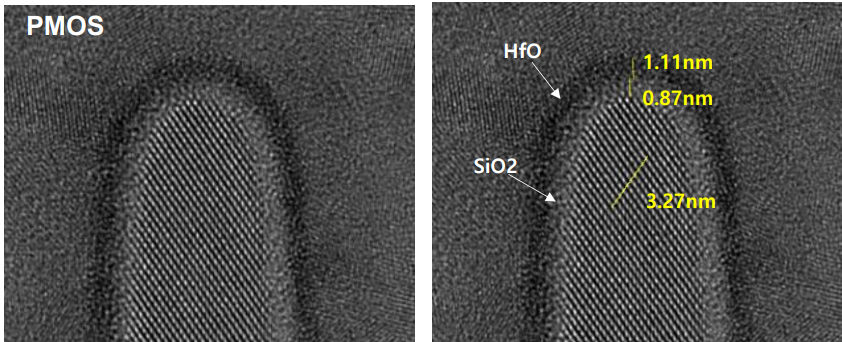

Our service entails in-depth analysis of semiconductor fabrication processes, encompassing critical parameter characterization such as deposition rates, etching profiles, doping concentrations, thermal behaviors, and functional block insights. This supports R&D endeavors by furnishing invaluable insights for process optimization and technological advancements, ensuring clients remain at the forefront of innovation.

Furthermore, we conduct meticulous investigation and analysis of process-induced defects in semiconductor devices, including contamination, delamination, irregular patterns, interface anomalies, and functional block analysis. These findings serve as pivotal evidence in IT litigation cases, offering profound insights into process-related issues and their ramifications on device performance.

In addition to legal compliance, our Process Analysis services provide robust defense strategies for clients embroiled in IT litigation, offering expert analysis, documentation, and testimony to fortify litigation defense efforts and safeguard intellectual property rights. Moreover, through yield enhancement and process optimization, we assist semiconductor manufacturers in bolstering manufacturing efficiency, reducing costs, and sustaining competitiveness.

Our analytical insights enable evidence-based decision-making across both R&D and litigation scenarios, empowering clients to navigate the intricate landscape of high-tech industries with confidence and conviction. With adeptness in semiconductor process characterization, defect analysis, yield enhancement, and process optimization, we empower clients to drive innovation, ensure legal compliance, and achieve unparalleled success in today’s ever-evolving high-tech landscape.

Services

- Process characterization

- Defect analysis

- Root cause analysis for yield loss

- Functional block analysis

- Process optimization

- Materials analysis

- Litigation support

Pricing

- Please contact us with the details of your project for consultation and pricing.

FAQ

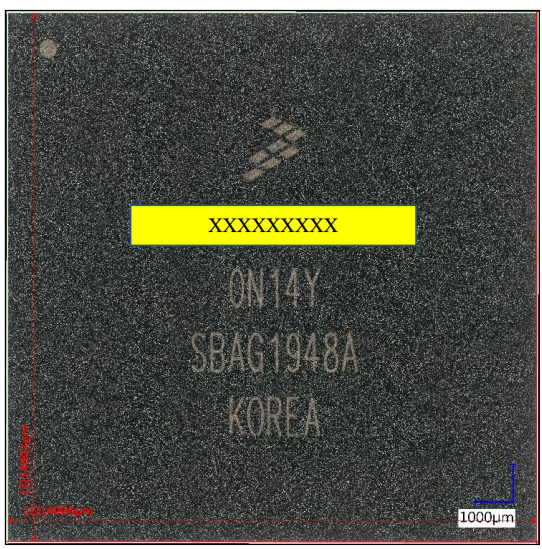

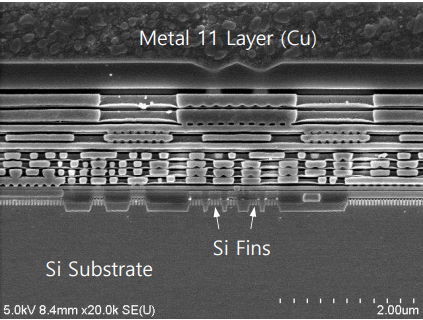

A: Process analysis involves the examination and characterization of semiconductor fabrication processes used to manufacture IC chips. It includes evaluating parameters such as deposition rates, etching profiles, doping concentrations, and material properties to ensure optimal performance and reliability of the final devices.

A: Process analysis is crucial for identifying and optimizing manufacturing processes to enhance product quality, reliability, and yield. It helps semiconductor manufacturers understand process variations, identify sources of defects, and implement corrective actions to improve overall process efficiency.

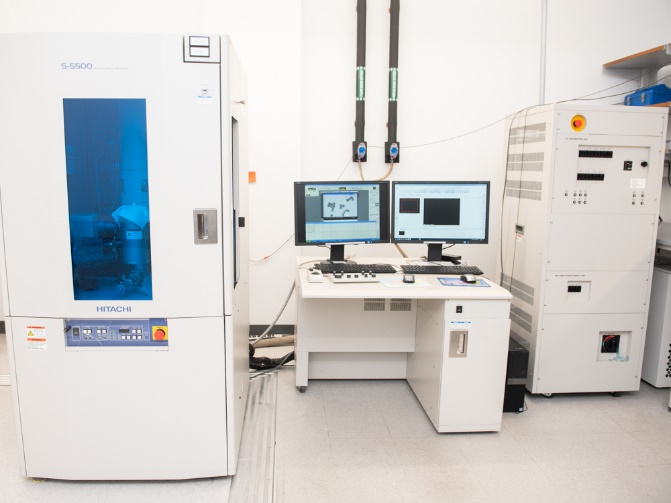

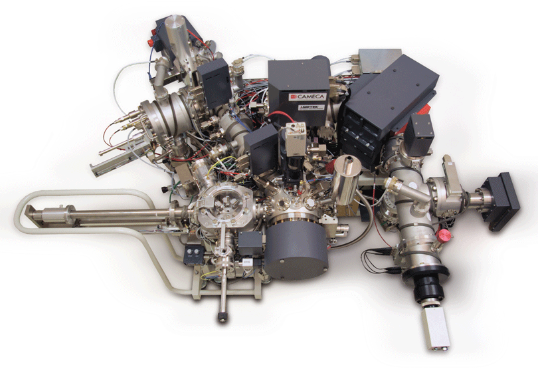

A: Equipment used for process analysis includes scanning electron microscopes (SEM), transmission electron microscopes (TEM), focused ion beam (FIB) systems, atomic force microscopes (AFM), X-ray photoelectron spectroscopy (XPS), secondary ion mass spectrometry (SIMS), and thermal analysis instruments, among others.

A: Parameters analyzed during process analysis may include deposition rates, film thickness, etching profiles, doping concentrations, crystallographic orientation, surface roughness, defect densities, and electrical characteristics of IC chip devices.

A: Process analysis helps identify and mitigate sources of defects and variability in semiconductor manufacturing processes, leading to improved yield, reduced scrap rates, and increased production efficiency.

A: Process analysis supports R&D efforts by providing insights into process variations, material properties, and device performance. It helps researchers optimize process parameters, develop new materials, and advance semiconductor technologies.

A: Yes, process analysis can identify root causes of device failures or reliability issues by analyzing factors such as material defects, process variations, and environmental stresses that may affect device performance over time.

A: Process analysis ensures consistent and reliable production of IC chip devices by monitoring process parameters, detecting deviations from specifications, and implementing quality control measures to maintain product quality and reliability.

A: Common challenges include process variability, contamination control, equipment limitations, data interpretation, and scalability of analytical techniques to meet the demands of advanced semiconductor technologies.

A: Outsourcing process analysis services allows companies to leverage specialized expertise, access advanced analytical equipment, and gain insights from experienced analysts without the need for large capital investments or maintaining in-house capabilities.