Package Analysis

Package Analysis

Overview

Our Package Analysis Service for IC (Integrated Circuit) Devices is designed to meet the rigorous demands of the high-tech industry by offering comprehensive testing and analysis solutions for semiconductor packages. Leveraging state-of-the-art equipment and expertise, we provide a suite of services tailored to ensure the reliability, performance, and quality of IC devices. With a focus on accuracy, efficiency, and customer satisfaction, we strive to be your trusted partner in semiconductor package analysis.

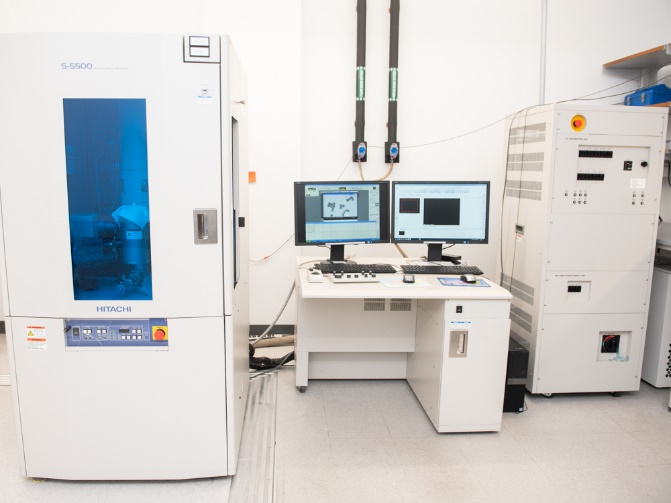

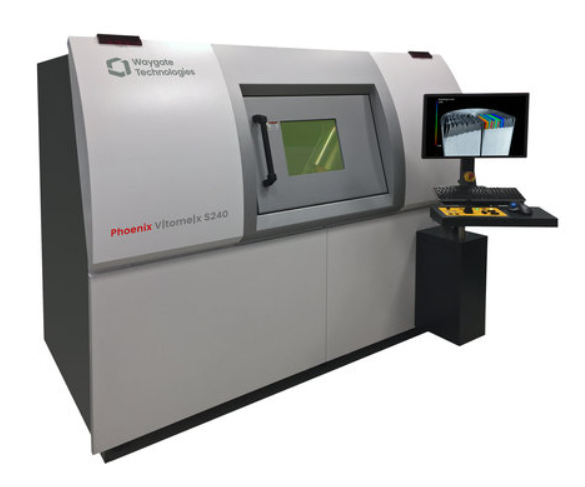

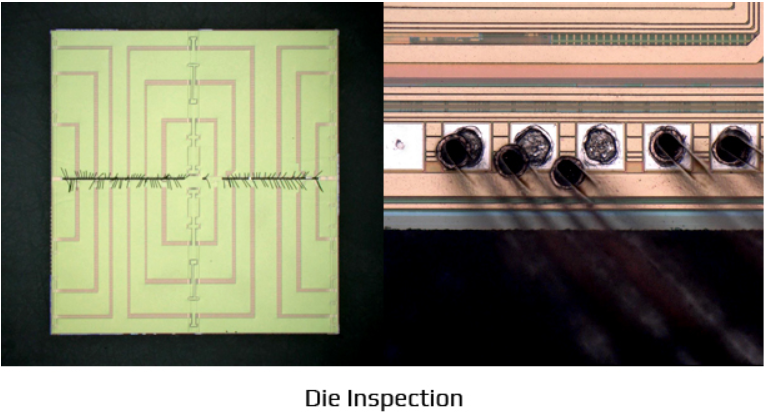

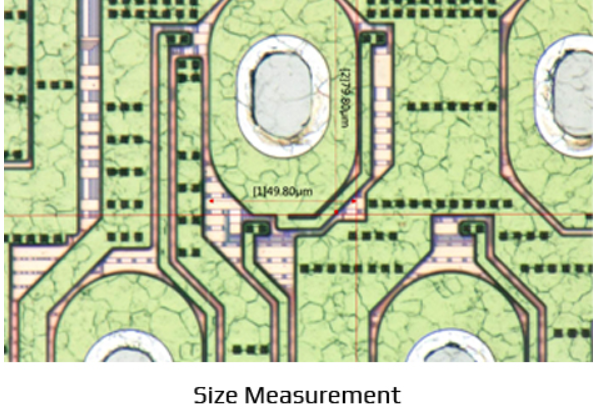

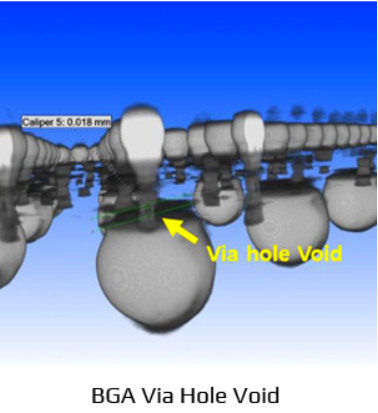

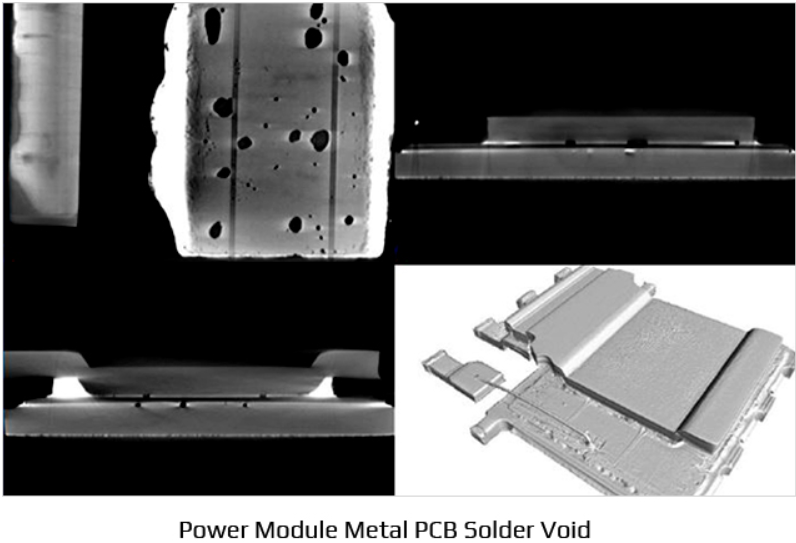

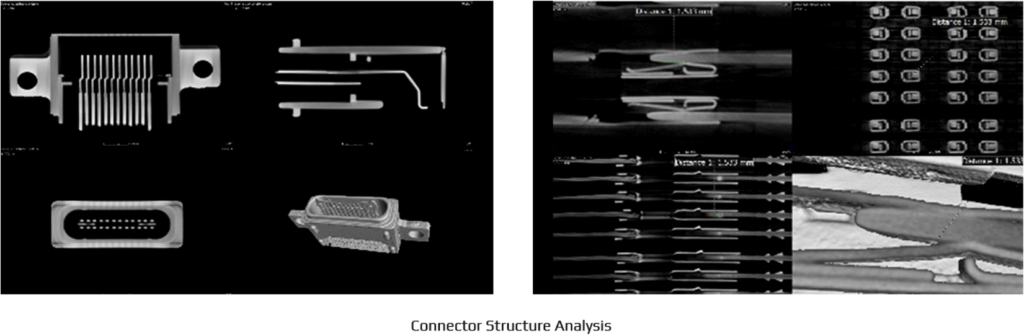

Our service offerings encompass a wide range of analyses to address various aspects of semiconductor package reliability and performance. We provide visual inspection services to detect surface defects, dimensional analysis to verify critical package parameters, X-ray inspection for non-destructive internal imaging, cross-sectional analysis for detailed structure examination, material analysis for composition verification, and thermal analysis for evaluating heat dissipation properties. Each analysis is conducted with precision and attention to detail to deliver actionable insights for optimizing package design and manufacturing processes.

Our Package Analysis Service offers numerous benefits to our clients in the high-tech industry. By ensuring the quality and reliability of semiconductor packages through rigorous testing and analysis, we help minimize the risk of device failures and costly recalls. Our services also aid in performance optimization by identifying design flaws, material defects, or process weaknesses early in the development cycle, leading to enhanced performance and yield. Additionally, our failure analysis capabilities enable us to troubleshoot package-related issues and implement corrective actions, reducing manufacturing defects, yield losses, and warranty claims. By ensuring compliance with industry standards and regulatory requirements, we enhance market acceptance and customer satisfaction, ultimately contributing to cost reduction and improved competitiveness.

In conclusion, our Package Analysis Service for IC Devices offers a comprehensive suite of testing and analysis solutions tailored to the unique needs of the high-tech industry. With our commitment to accuracy, reliability, and customer satisfaction, we strive to be your trusted partner in semiconductor package analysis. Whether you require visual inspection, dimensional analysis, X-ray inspection, cross-sectional analysis, material analysis, or thermal analysis, we are dedicated to delivering accurate, reliable, and actionable insights to support the success of your semiconductor packaging initiatives.

Services

- Visual inspection

- Dimensional analysis

- BGA analysis

- X-ray inspection (2D and 3D)

- Cross-sectional analysis

- Material analysis

- Thermal analysis

Pricing

- Please contact us with the details of your project for consultation and pricing.

FAQ

A: Package analysis involves testing and analyzing semiconductor packages to ensure their reliability, performance, and quality. It is essential for identifying defects, optimizing designs, and ensuring compliance with industry standards.

A: Package analysis can be conducted on various semiconductor packages, including leaded and leadless packages, surface mount devices (SMDs), ball grid arrays (BGAs), chip-scale packages (CSPs), and more.

A: Common techniques used in package analysis include visual inspection, dimensional analysis, X-ray inspection, cross-sectional analysis, material analysis, thermal analysis, electrical testing, and environmental testing.

A: Parameters evaluated during package analysis may include package dimensions, lead pitch, lead coplanarity, internal structure, wire bonds, die attachment, solder joints, material composition, thermal properties, electrical characteristics, and environmental performance.

A: Package analysis helps semiconductor manufacturers ensure the quality and reliability of their products, optimize package designs and manufacturing processes, troubleshoot issues, minimize defects and failures, and ensure compliance with industry standards and regulations.

A: Package analysis provides valuable insights into the performance and reliability of semiconductor packages, allowing manufacturers to identify potential issues early in the development cycle, make informed design decisions, and implement effective quality control measures.

A: Common failure modes identified through package analysis may include solder joint defects, wire bond fractures, delamination, moisture-induced failures, thermal overstress, electrical shorts or opens, and manufacturing defects.

A: Package analysis is integral to reliability testing and qualification processes, helping manufacturers assess the long-term performance and durability of semiconductor packages under various environmental conditions, stressors, and operating conditions.

A: Package analysis enables manufacturers to investigate and diagnose issues reported by customers, identify root causes of failures or defects, implement corrective actions, and prevent similar issues in future product batches.

A: Yes, various industry organizations such as JEDEC, IPC, and ASTM International provide standards, guidelines, and best practices for conducting package analysis, ensuring consistency, reliability, and quality in testing protocols.