Dynamic Mechanical Analysis (DMA)

Dynamic Mechanical Analysis (DMA)

Overview

DMA analysis is a fundamental method in materials science and engineering, allowing for the detailed study of a material’s response to mechanical forces and temperature variations. It plays a pivotal role in understanding properties such as stiffness, damping, viscoelasticity, and glass transition temperature.

DMA operates by subjecting a sample to a dynamic mechanical force, typically sinusoidal in nature, while simultaneously varying temperature, time, or frequency. The sample’s response to this dynamic force is measured, including its stress, strain, and phase angle. By analyzing this data, DMA provides insights into the material’s mechanical behavior as it undergoes deformation, transitions, and relaxation.

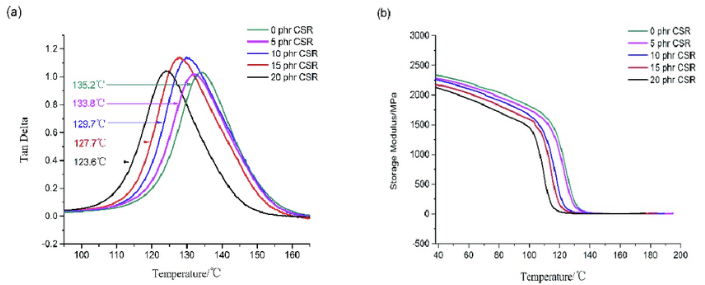

The versatility of DMA analysis allows for the investigation of various mechanical properties, such as storage modulus (stiffness), loss modulus (damping), and tan delta (a measure of viscoelastic behavior). DMA is applicable to a wide range of materials, including polymers, composites, elastomers, and biomaterials.

Outermost Technology’s DMA Analysis services offer precise measurements of mechanical properties, enabling you to gain a deeper understanding of material behavior and performance. Whether you are developing new materials, optimizing product design, or studying the mechanical response of biomaterials, our state-of-the-art DMA equipment and experienced analysts provide the insights you need.

Services

- Elastic modulus

- Loss modulus

- Tan δ (damping factor)

- Glass transition temperature (Tg)

- Melting and crystallization temperature

- Viscoelastic behavior

Pricing

- Regular service: Starts from $400 per sample with 5 – 7 days turnaround.

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Equipment

- Force range: 0.001 N ~ 18 N

- Force resolution: 0.001 N

- Strain resolution: 1 nanometer

- Modulus range: 10E3 to 3x10E12 Pa

- Modulus precision: +/- 1%

- Tan δ range: 0.0001 ~ 10

- Tan δ sensitivity: 0.0001

- Tan δ resolution: 0.00001

- Frequency range: 0.01 ~ 200 Hz

- Dynamic sample deformation range: +/- 0.5 to 10,000 µm

- Temperature range: -150 ~ 600°C

- Heating rate: 0.1 to 20°C/min

- Isothermal stability: +/- 0.1°C

- Automated furnace movement: Yes

- Teme/temperature superposition software: Yes

FAQ

A: Dynamic Mechanical Analysis (DMA) is an analytical technique used to study the mechanical behavior and properties of materials by subjecting them to dynamic mechanical forces, temperature variations, or frequency changes.

A: DMA analysis works by applying a dynamic mechanical force (typically sinusoidal) to a sample while simultaneously varying temperature, time, or frequency. The response of the sample, including stress, strain, and phase angle, is measured to understand its mechanical behavior.

A: DMA can be applied to a wide range of materials, including polymers, composites, elastomers, biomaterials, and more. It is useful for characterizing mechanical properties in materials science, engineering, and other fields.

A: DMA analysis provides information about a material’s mechanical properties, such as stiffness (storage modulus), damping (loss modulus), viscoelasticity, and glass transition temperature. It helps in understanding how materials respond to dynamic forces and temperature changes.

A: DMA analysis finds applications in various industries, including automotive, aerospace, polymer research, biomaterials, and more. It is used to optimize product design, assess material performance, and study viscoelastic behavior.

A: In materials development, DMA helps researchers understand the mechanical properties of new materials and assess their suitability for specific applications. It aids in tailoring material formulations for desired performance characteristics.

A: Yes, DMA can be employed in quality control to assess the consistency and performance of materials, ensuring that products meet specified mechanical requirements and standards.

A: Outermost Technology’s DMA Analysis services offer precise measurements of mechanical properties and have experienced analysts. Whether you are researching new materials, optimizing product designs, or studying biomaterial behavior, our DMA services provide valuable insights into material mechanics.

A: In biomaterials research, DMA can help assess the mechanical properties of tissues, medical devices, and implants. It is used to study the viscoelastic behavior of biomaterials and their response to mechanical stresses.

A: DMA analysis provides critical data for polymer research by characterizing properties like glass transition temperature, stiffness, and damping. It aids in designing polymers for specific applications and understanding their behavior under dynamic conditions.