3D X-ray CT Scanning

3D X-ray CT Scanning

Overview

3D X-ray CT scanning isn’t just about seeing inside objects; it’s about unraveling the intricate details of materials and devices, pinpointing anomalies, and solving complex challenges in research and industry.

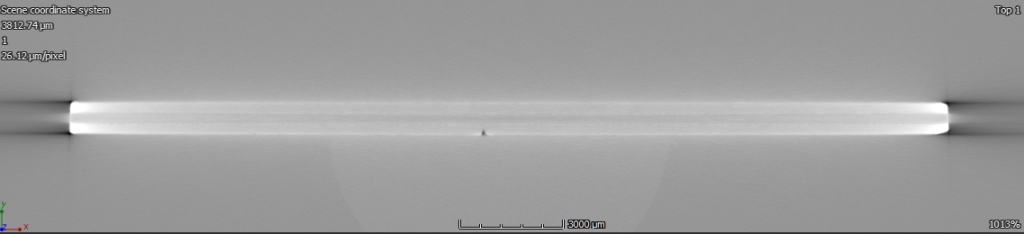

At its core, 3D X-ray CT analysis is a powerful imaging technique that combines X-ray technology with advanced computational algorithms to create detailed three-dimensional representations of objects, materials, and devices. It achieves this by capturing a multitude of X-ray images from various angles and subsequently reconstructing them into precise cross-sectional slices, offering an immersive 3D model of the subject. This non-destructive approach allows us to delve deep into materials and devices, identifying defects, failures, and structural intricacies with unprecedented accuracy.

Our 3D X-ray CT analysis service is a game-changer in the realm of materials and device analysis, particularly focused on failure analysis. In manufacturing and materials science, it plays a pivotal role in identifying material defects, delving into the root causes of failures, and optimizing the design and performance of materials. For electronic devices and components, it unveils hidden flaws, investigates solder joint integrity, and aids in resolving intricate electronic failures. Whether you’re in aerospace, automotive, electronics, or any industry reliant on materials and devices, 3D X-ray CT analysis is a powerful ally in ensuring product reliability and innovation.

Our 3D X-ray CT analysis service empowers you to harness the full potential of this transformative technology. Whether you’re conducting failure analysis, materials characterization, or device optimization, our state-of-the-art instrumentation and expert analysts ensure you gain the insights needed to address your unique challenges and objectives. We collaborate closely with you to uncover the hidden dimensions of materials and devices, providing invaluable data for informed decision-making and innovative solutions.

Services

- Regular service: Starts from $350/hour with 4 – 7 days turnaround. Expedited service available.

- For a comprehensive overview of our pricing structure, please log in to the Bee Portal.

Pricing

$300/sample that includes 3 images. 4 -6 days of turnaround.

FAQ

A: 3D X-ray CT analysis is an imaging technique that uses X-rays to create detailed three-dimensional representations of materials and devices. It works by capturing multiple X-ray images from different angles and reconstructing them into a 3D model to analyze internal structures and defects.

A: 3D X-ray CT analysis is used for failure analysis, defect identification, materials characterization, and optimizing device performance across various industries, including manufacturing, electronics, aerospace, and automotive.

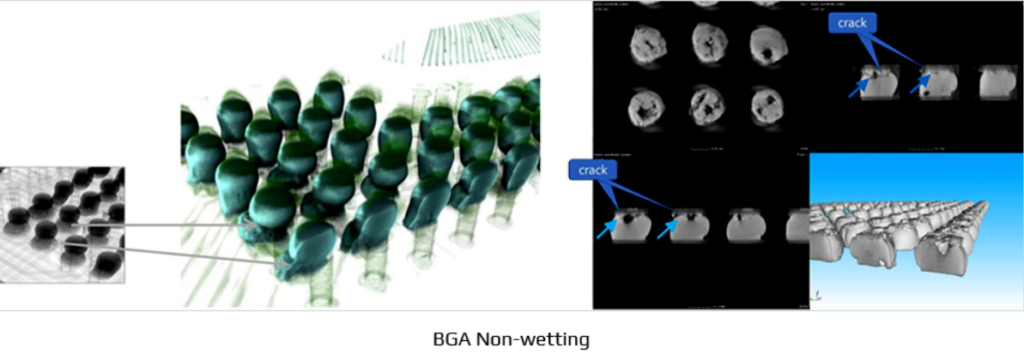

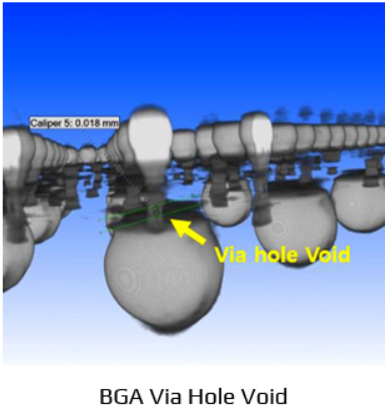

A: 3D X-ray CT analysis reveals internal defects, such as voids, cracks, inclusions, and porosity, helping pinpoint material issues that can lead to failures or performance problems.

A: In electronic device analysis, 3D X-ray CT can investigate solder joint integrity, identify wirebond issues, locate short circuits, and examine package integrity, contributing to resolving complex electronic failures.

A: Yes, 3D X-ray CT analysis is non-destructive, allowing for in-depth examination without damaging the materials or devices under investigation.

A: The speed of a 3D X-ray CT analysis varies depending on the sample size and complexity but typically takes anywhere from a few minutes to an hour.

A: Yes, 3D X-ray CT analysis can provide quantitative data, including measurements of dimensions, porosity, density, and defect sizes, aiding in materials and device characterization.

A: Yes, 3D X-ray CT analysis can be applied to a wide range of materials and devices, including large and complex structures, to investigate internal features and defects.

A: You can request 3D X-ray CT analysis services from specialized laboratories or analytical service providers. Contact them to discuss your specific analysis needs and to arrange for testing.

A: Yes, 3D X-ray CT analysis can be customized to address specific materials and device analysis challenges, ensuring that the analysis meets your unique requirements and objectives.